Bold Maker is helping the food & candy industry work better, work smarter, and faster!

We understand that time is money and reliability is worth more than that. In the modern commercial kitchen or food manufacturing facility, tracking your productivity is critical to fulfilling current orders and securing future orders.

Is De-molding your molds an obvious bottleneck in your production line?

Bold Maker produces the best molds to help make de-molding easier. Pair our Food-Grade Platinum Silicone molds with a refined and efficient process and you have an unbeatable combination. You might want to ask, is it possible to produce 1 million, 2 million, 5 million candies per month with hand de-molding? Well the answer is YES, because we have partners out there that are doing it.

Speed is the name of the game here, and Bold Maker is confident it can make you the fastest candy-makers around. Here are a few tips for getting the most out of de-molding your molds!

Oils and Waxes

Some oils and waxes can be applied to the surface of the mold before filling to make de-molding even easier. Coconut Oil and Sesame seed oil can be easily applied in an aerosolized form. Food-grade waxes (Carnauba - which has a ‘GRAS’ Generally Recognised as Safe regulatory rating by the FDA at time of writing) is also used.

Oils and waxes are generally applied to the mold face before casting, and one coating may last several casting cycles before a re-application is needed. Creating a natural oil barrier generally means certain foods would be easier to clean off the mold itself. A commercial dishwasher-safe soap, which is safe to use when cleaning Bold Maker molds, is a good way to clean any excess oil or wax at the end of production.

It is always important to consider the type of product you are casting, and whether this method is necessary for that particular type of product.

De-molding by Hand

De-molding by hand can be a tedious task, especially given there is currently no automated solution. There are however ways you can de-mold quickly and effectively. The size of mold, type of product being casted, and the mold material itself are factors to consider for best practice. Luckily, we got it covered.

Silicone Molds

Fold Method

Laying a mold face down on to a suitable surface, peel one edge of the mold upwards, prying the product from the mold one by one. By using a brushing motion with your hand, you can eventually de-mold more than one piece at a time. This is especially suitable for silicone molds, and gummies which can be manipulated without spoiling the product.

Pressure Method

Lay the mold face down, press on the backside of the mold to release the surface of the candy. Some candy mixtures may stick to sheet pans or wax paper sheets. This can be used to your advantage to pull the candy from the mold. Then the candy can be quickly brushed into a bowl or container. Peel the short edge of the mold back on itself to allow the product to fall out of the casting or remain stuck to the sheet. Then transfer the candies from the sheet to another container. This is a great method that requires very few or no touches per candy, meaning it can be faster and more sanitary.

Bold Maker silicone molds are malleable, can be easily manipulated, and will always return back to their original state. We are constantly striving to make it easier for the end customer to up their game, increase efficiency, and deliver a high class product with the best production materials.

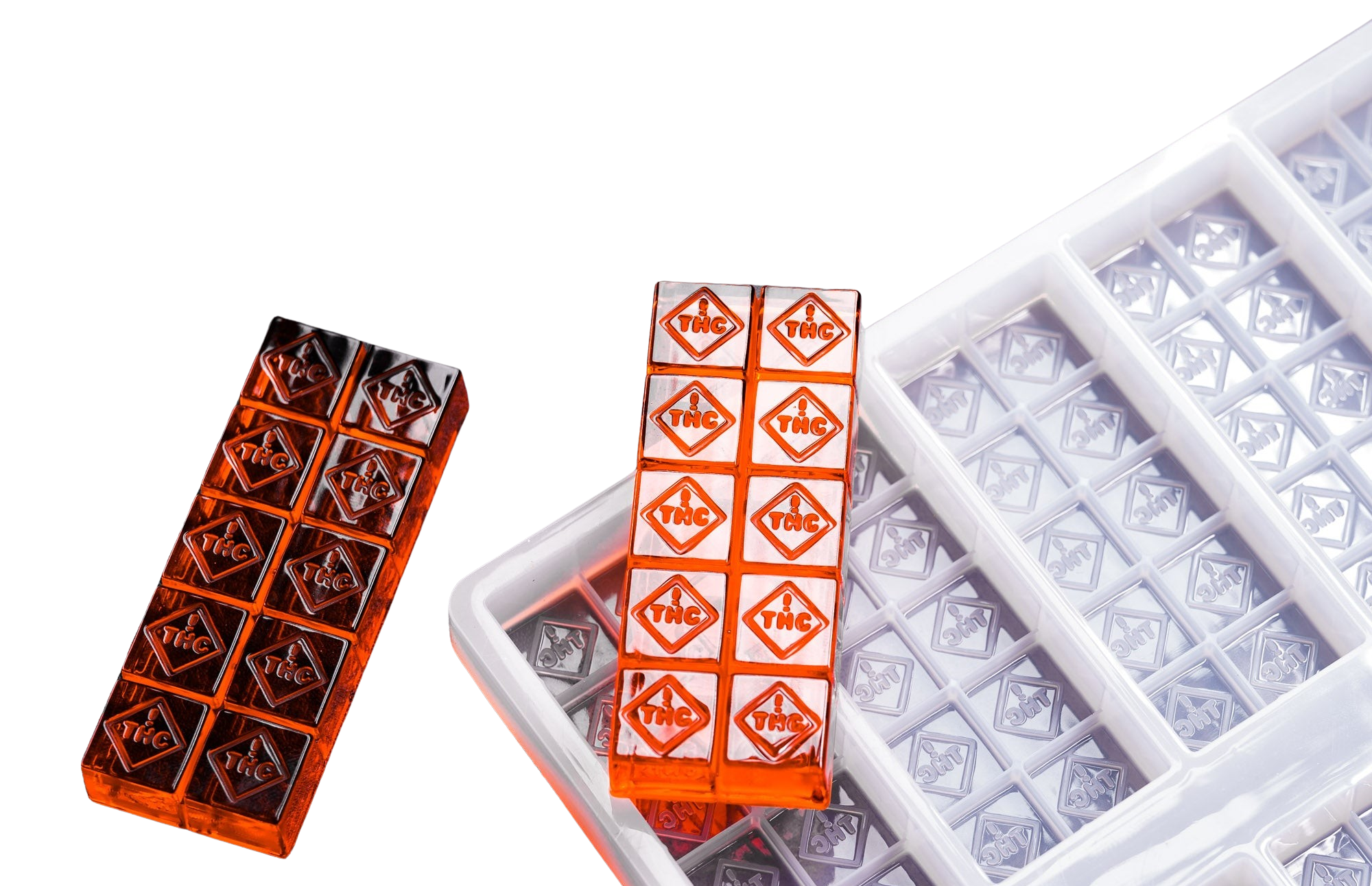

Polycarbonate Molds

Our polycarbonate molds do not warp or shrink, can be baked or frozen, and carry an extended mold life of 8+ years. This allows for fast de-molding during the production process, without fear of the mold warping and affecting the product. Mainly used for chocolate, our best practice for this type of mold is a simple tap with a hard, clean surface. You can see this method and our molds in action below.

Chocolate must be properly tempered when poured into any polycarbonate mold. The mold works because chocolate shrinks slightly while cooling under proper temper conditions. Once your chocolates are cooled they will be easily de-molded with a swift tap on a hard table. Do not worry, the molds will never break! Place a stack of clean wax baking sheets under the tray to catch chocolates as they fall.

Chocolatiers achieve greatest success with Bold Maker molds when they are used and cleaned properly. Polycarbonate molds should be clean and dry of any moisture prior to filling. This allows the chocolate to properly cool and release easily from the mold.

No matter how big or small your production line, it will always take time to create an efficient process, using the right tools and the right staff, but rest assured Bold Maker molds are designed to make sure you get it right every time.

Shop our Silicone and Polycarbonate Molds!